Oxi-Tech brings cutting edge chemical-free cleaning solution to the agritech industry

Cornwall-based Oxi-Tech Solutions Ltd is working with the UK Agri-Tech Centre to improve efficiency for farmers while reducing the carbon footprint and improving the sustainability of dairy farming.

Oxi-Tech Solutions, which joined a showcase of South West tech firms in June 2024 organised by Tech South West, has developed Pulse Oxidation technology - a unique, patented, system that creates charged oxygen within water by using small amounts of electricity, thus creating chemical-free disinfection with a multitude of benefits to dairy farmers.

The project with the UK Agri-Tech Centre is funded in collaboration between Defra and Innovate UK’s Transforming Food Production Challenge, and aims to demonstrate that chemical-free water disinfection can be used to replace chemicals and hot water in the robotic milking system.

For the trial, Oxi-Tech’s Pulse Oxidation unit was temporarily installed at the South West Dairy Development Centre (SWDDC), using the Lely Astronaut A5 milking robots. The SWDDC is run by the UK Agri-Tech Centre, working alongside its farming partner, Steanbow Farms.

Due to the design of the Lely robot’s cleaning system integration was simple; the supply pipe to the hot water cylinder was moved to the Oxi-Tech unit via a filter and the unit’s output pipe fitted in place of the cylinder output.

A power supply was then provided.

The water remains charged for up to 30 minutes, allowing the cleaning solution to clean the entire delivery line. After 30 minutes the solution returns back to water, leaving no chemical to dispose.

The Lely robot operates 24 hours a day, 365 days a year and handles the milking of the herd to allow farmers the flexibility to concentrate on different areas of their business.

The aim is to automatically milk cows when they are ready, optimising yields in a relaxing environment for the cow.

Cows approach and enter the robots, where they are identified, allocated a feed and milked without any interaction required from the farmer.

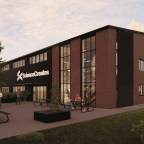

The facility

Located near Shepton Mallet, Somerset, it is a purpose-built unit specifically constructed for this type of research and development project.

Utilising a 180-cow herd, the trial is in a monitored environment which means the UK Agri-Tech Centre can fully analyse the impact of the trial without disturbing the operation of the farm. This means that the same work is conducted on the farm without holding up the day-to-day operations of the unit.

It also allows the project to be trialled in a dedicated area that can be monitored and adapted to meet the needs of the business.

Rob Morrison, Head of Farms at the UK Agri-Tech Centre, said: “The SWDDC is at the forefront of innovation in the dairy sector, offering a unique service that supports the development and adoption of cutting-edge agricultural technology.

“Funded by Innovate UK, SWDDC plays a pivotal role in driving efficiency and sustainability in modern dairy farming.

“A key feature of SWDDC is its advanced monitoring and data collection system, which provides unprecedented insights into herd health, milk production, and overall farm management.

“This real-time data empowers innovators to improve their products and refine designs to better suit the demands of the farming environment, ensuring solutions are both practical and effective.”

The benefits

It poses none of the risks of traditional cleaning chemicals to animals and farmers as, unlike chemical cleaners, Oxi-Tech works with cold water which eliminates significant costs and associated CO2 from heating the water.

This means there are energy and carbon dioxide savings of as much as 5 tonnes per year on a typical UK dairy farm, achieved mostly through the reduction in hot water usage, and the elimination of waste around the production, transport and disposal of plastic containers with chemical cleaners.

In addition to it being controllable thanks to finely controlled doses and concentration, and easily connected due to intelligent control with remote access, it is easy to use and maintain as cells are replaced during regular maintenance of existing milking equipment.

This technology can be utilised across a spectrum of disinfection applications including: Agri-tech, water supply, built environment and can be used in the destruction of pathogens such as Staphylococcus, Streptococcuss, E. coli, Legionella and Biofilms.

Paul Morris, Chief Executive at Oxi-Tech Solutions, said: “With Pulse Oxidation we have a robust and reliable platform that has consistent output.

“We are seeing significantly improved performance in comparison to conventional disinfection, with the added downstream carbon and environmental benefits.

“We have also assisted the Lely robotics team with testing different parts of their system which aren’t normally looked into in such detail.

“This has helped us to absorb a significant amount of knowhow and experience from running the programme, and we are working with a world class team of experts who are really supportive and share their knowledge freely.”

To watch a video of the technology in action, visit https://www.youtube.com/watch?v=T8Y3X2HM3BA

For more information about the UK Agri-Tech Centre, visit www.ukagritechcentre.com

To find out more about Oxi-Tech Solutions Ltd. visit www.oxitechsolutions.com